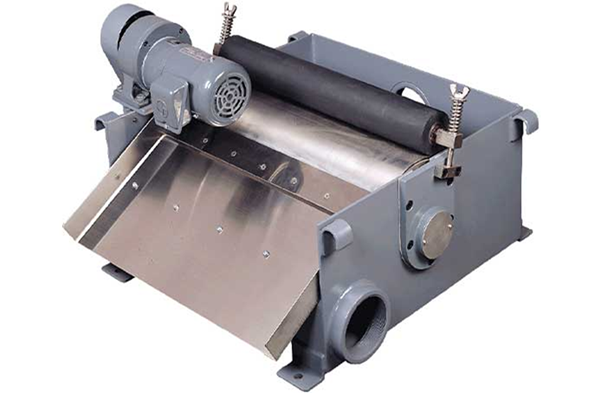

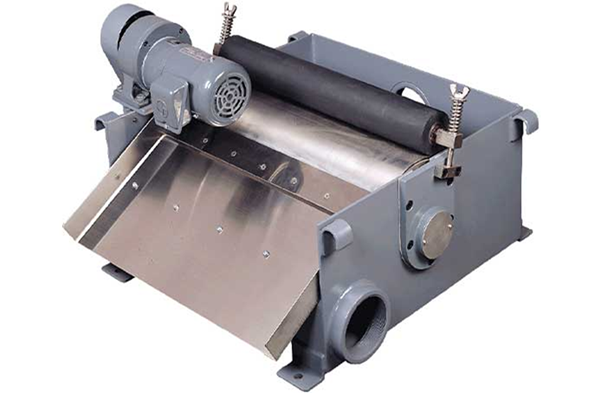

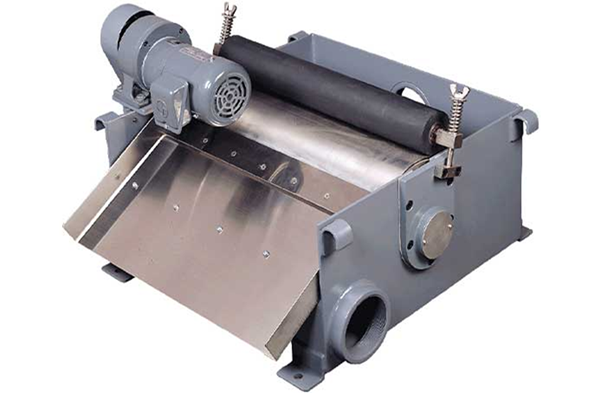

Magnetic separators are well suited to processes where ferrous and non-ferrous contaminants are mixed

with water-based coolants or straight cutting oils. They can also be used to enhance chip processing

tasks and help you get the most out of your industrial filtration equipment.

Remove ferrous material, including sludge and chips, from both water soluble and neat oils with high

intensity ferrite or rare earth magnets. Typical applications include centre less and heavy stock

removal grinding machines, honing, and gear cutting machinery.

The magnetic separator is a highly efficient fluid filtration method that removes high levels of ferrous contaminants from liquid, helping with recycle and reuse goals.

The magnetic separator provides continuous operation and reduces downtime by up to 50%.