Powerful magnetic drum conveyor MMS

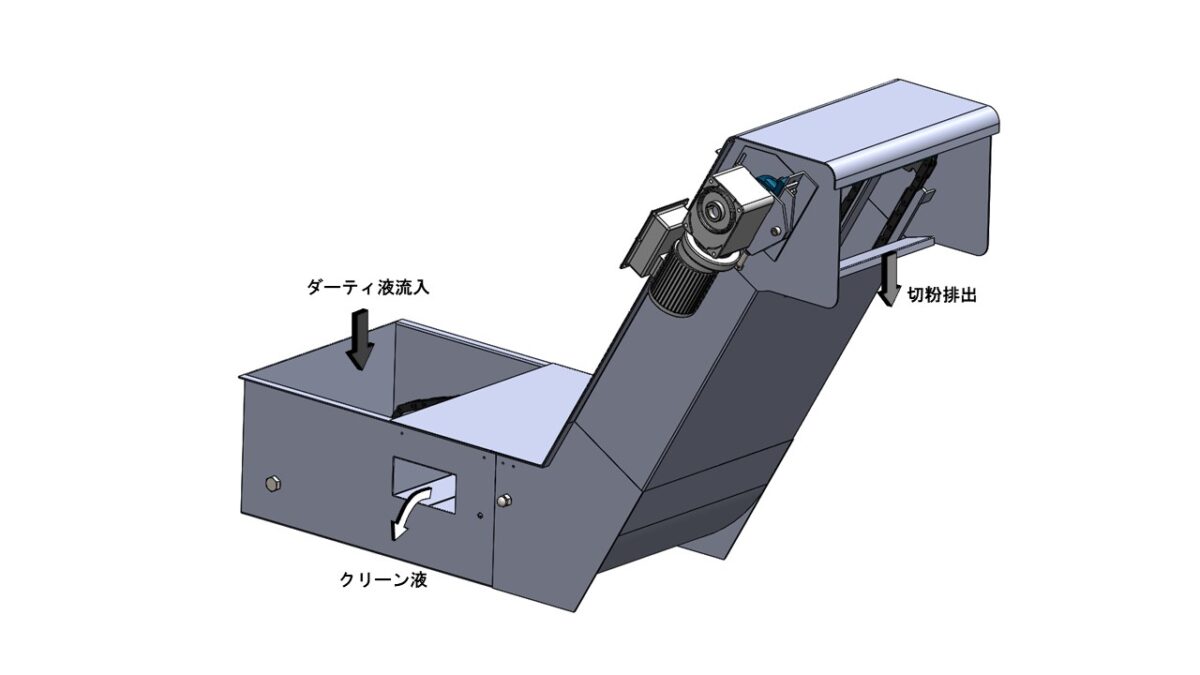

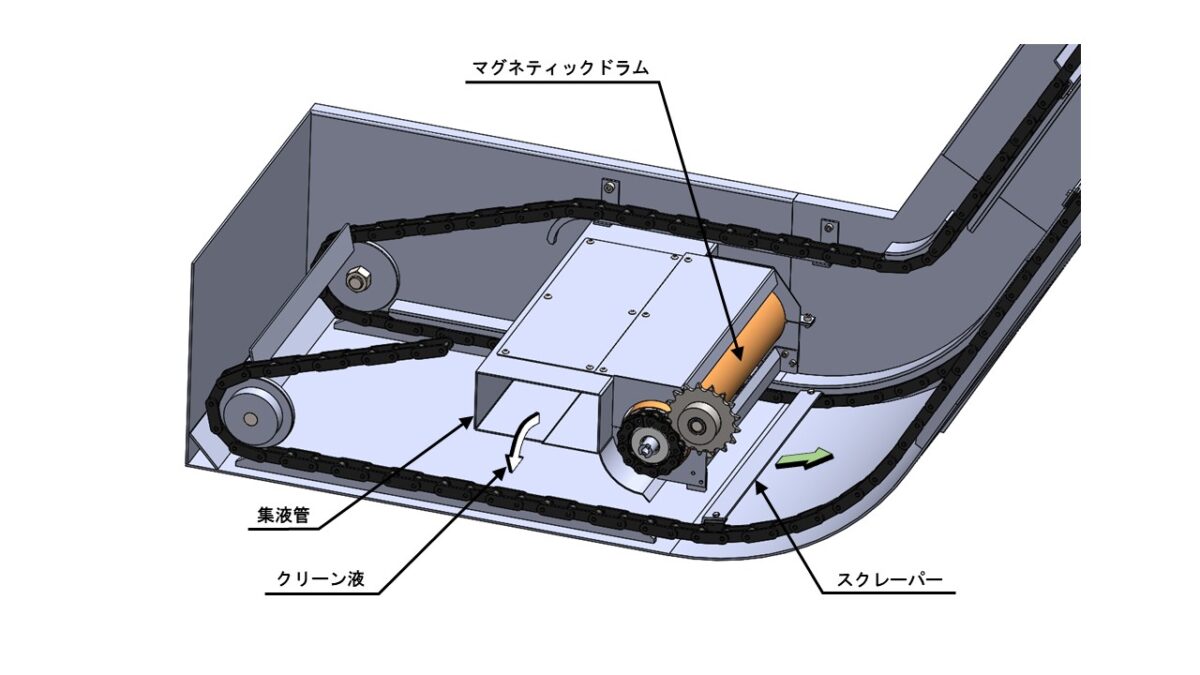

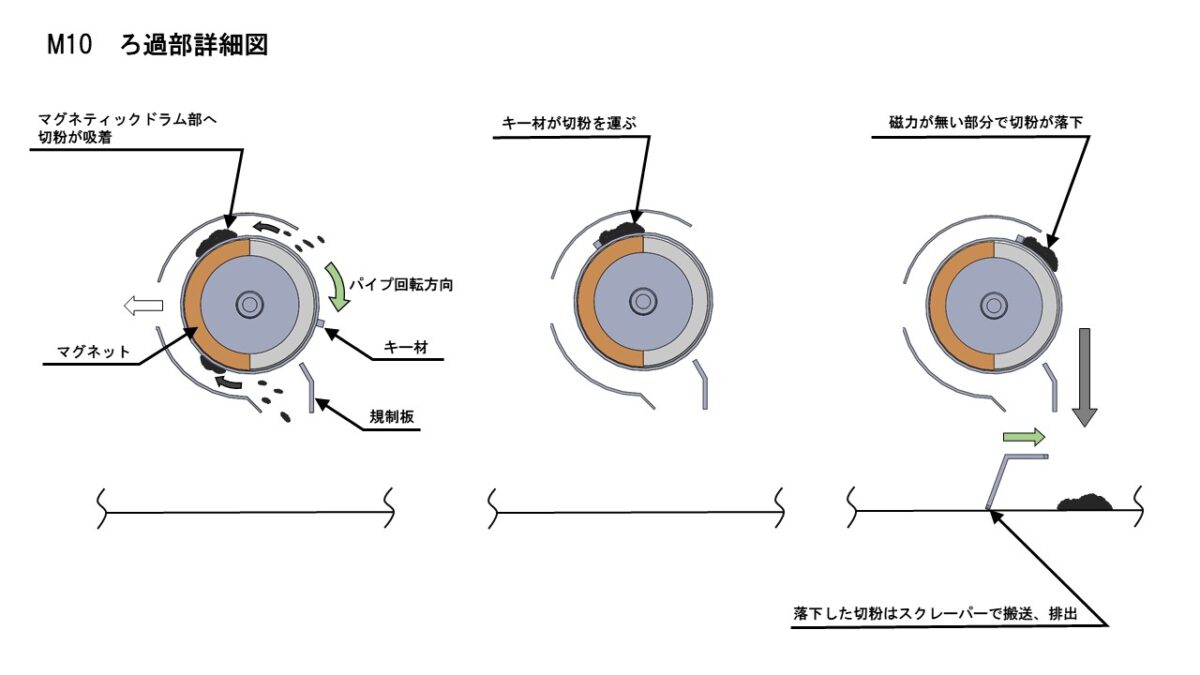

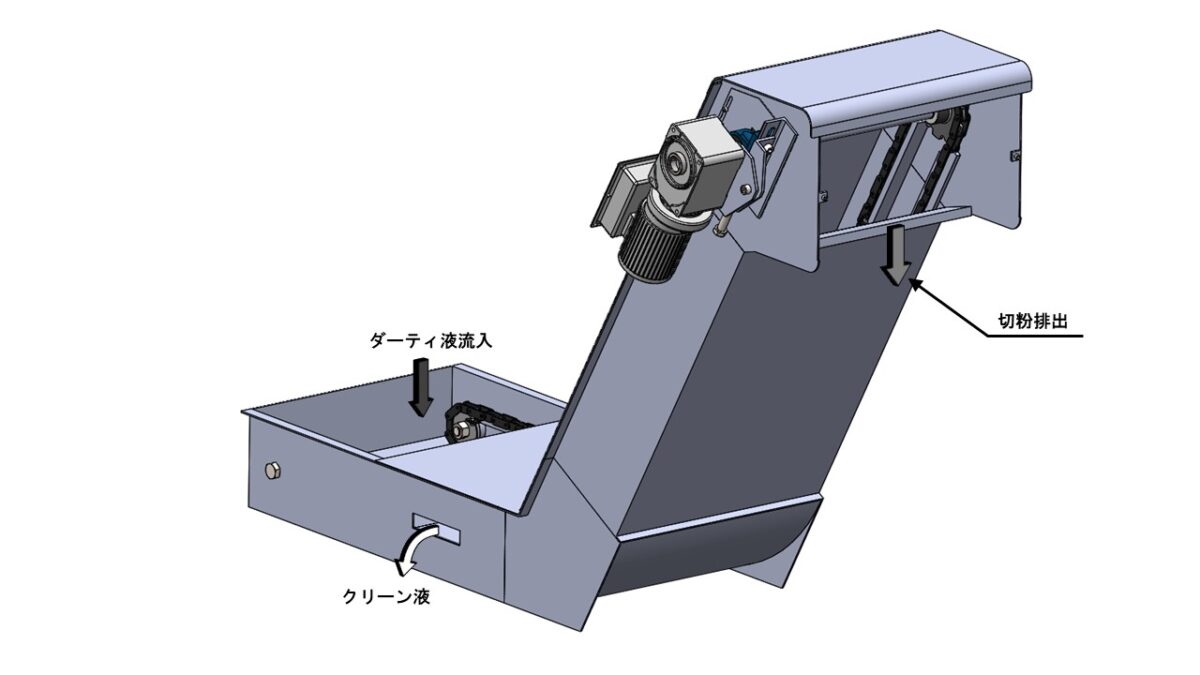

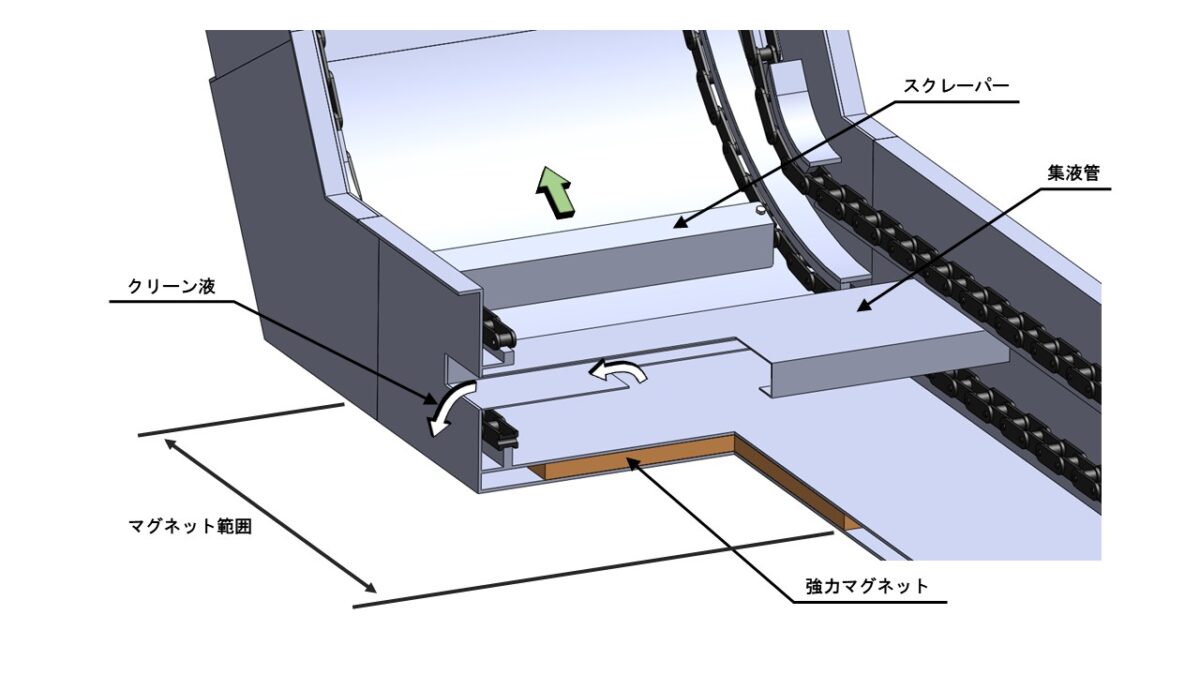

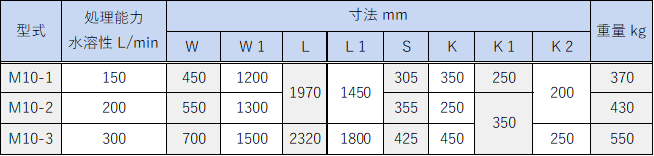

Super strong magnetic drum conveyor M10

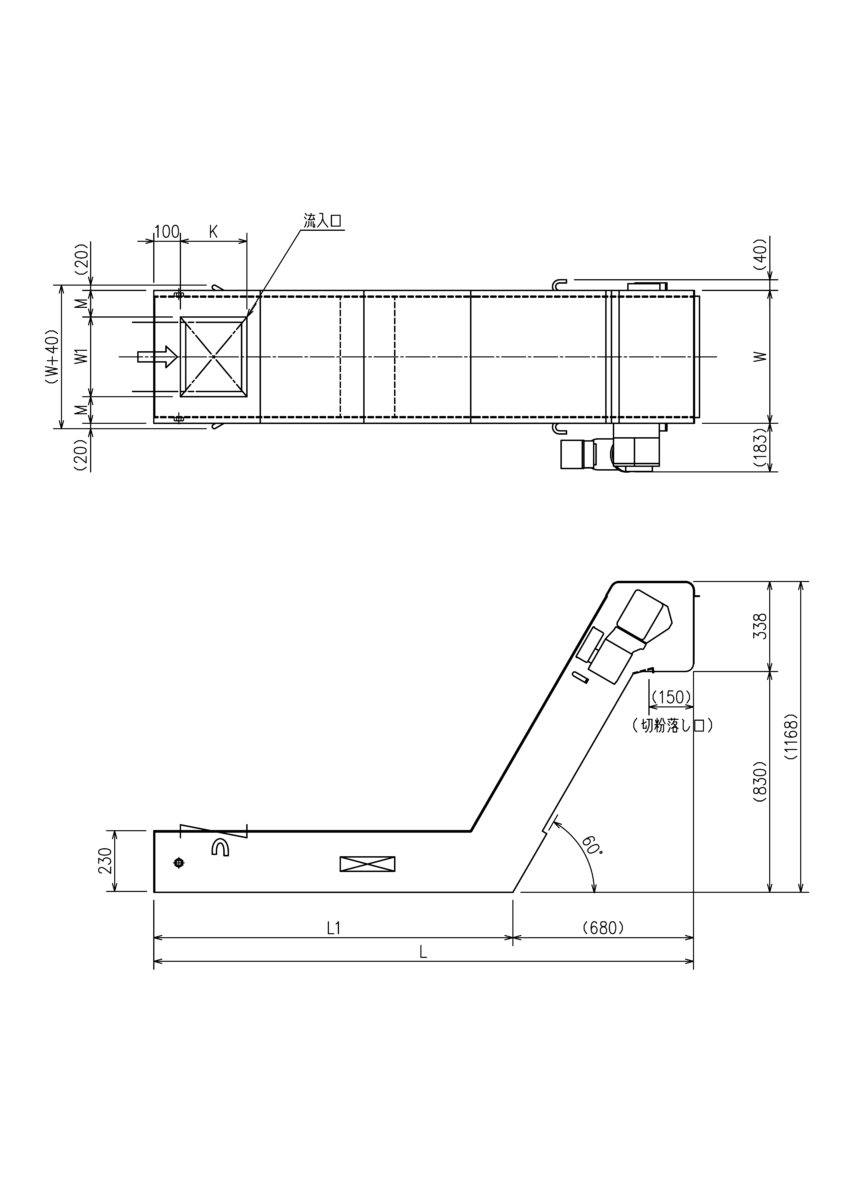

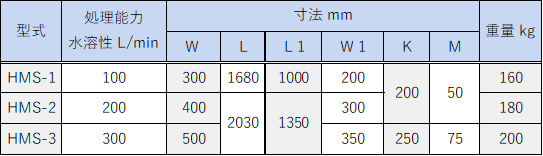

Powerful magnetic drum conveyor HMS

#30 Super strong magnetic drum conveyor M10

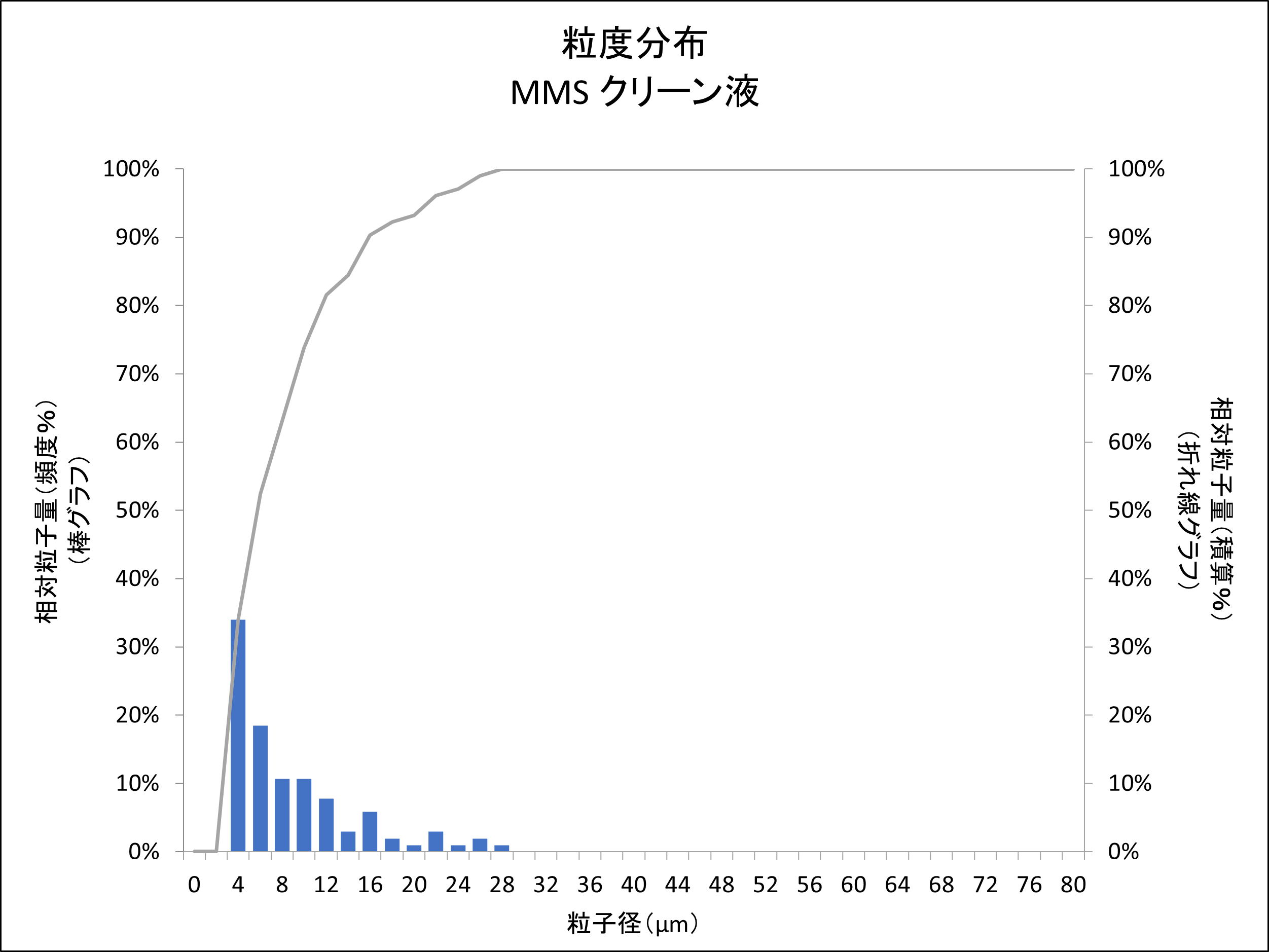

MMS

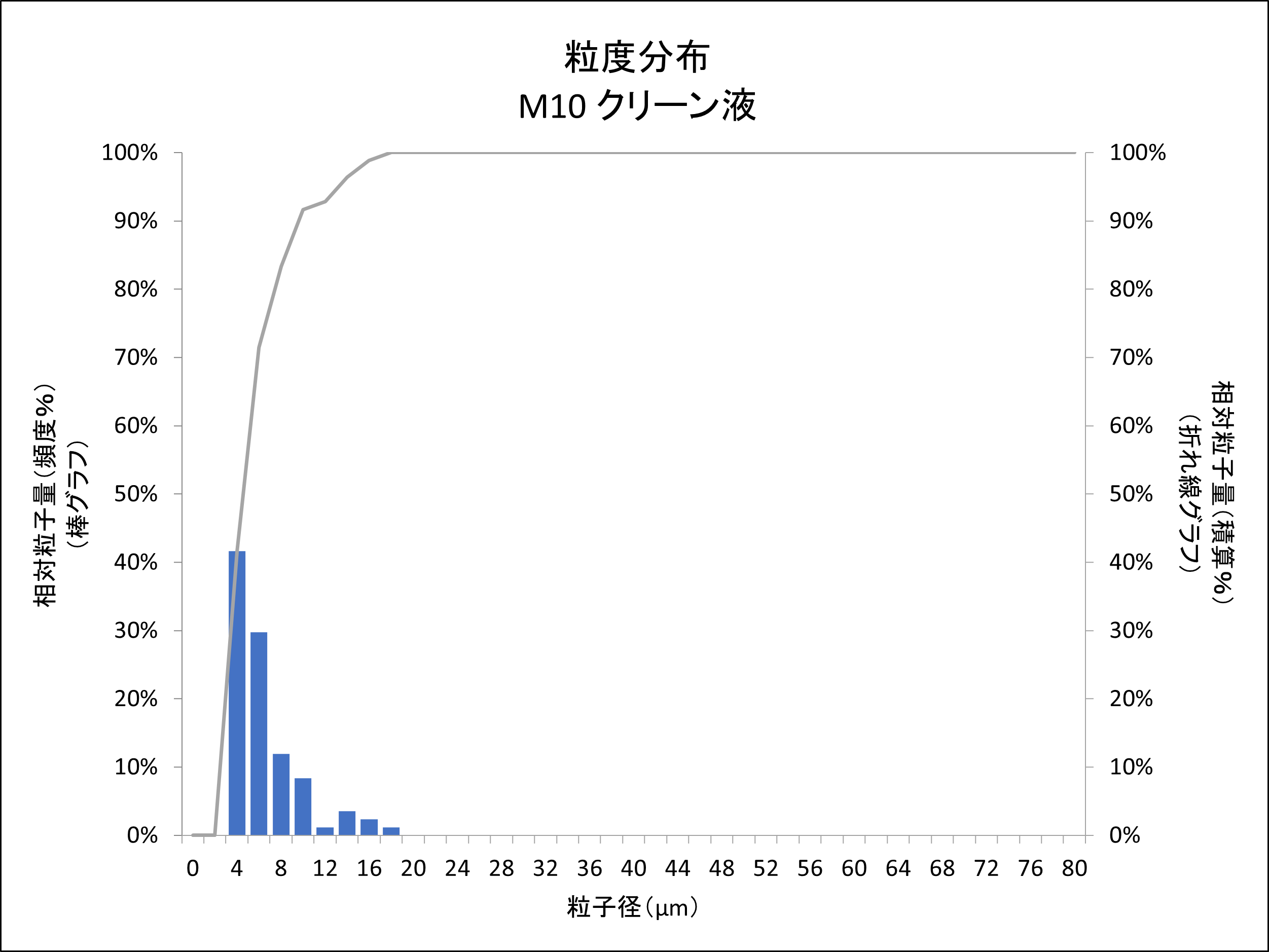

M10

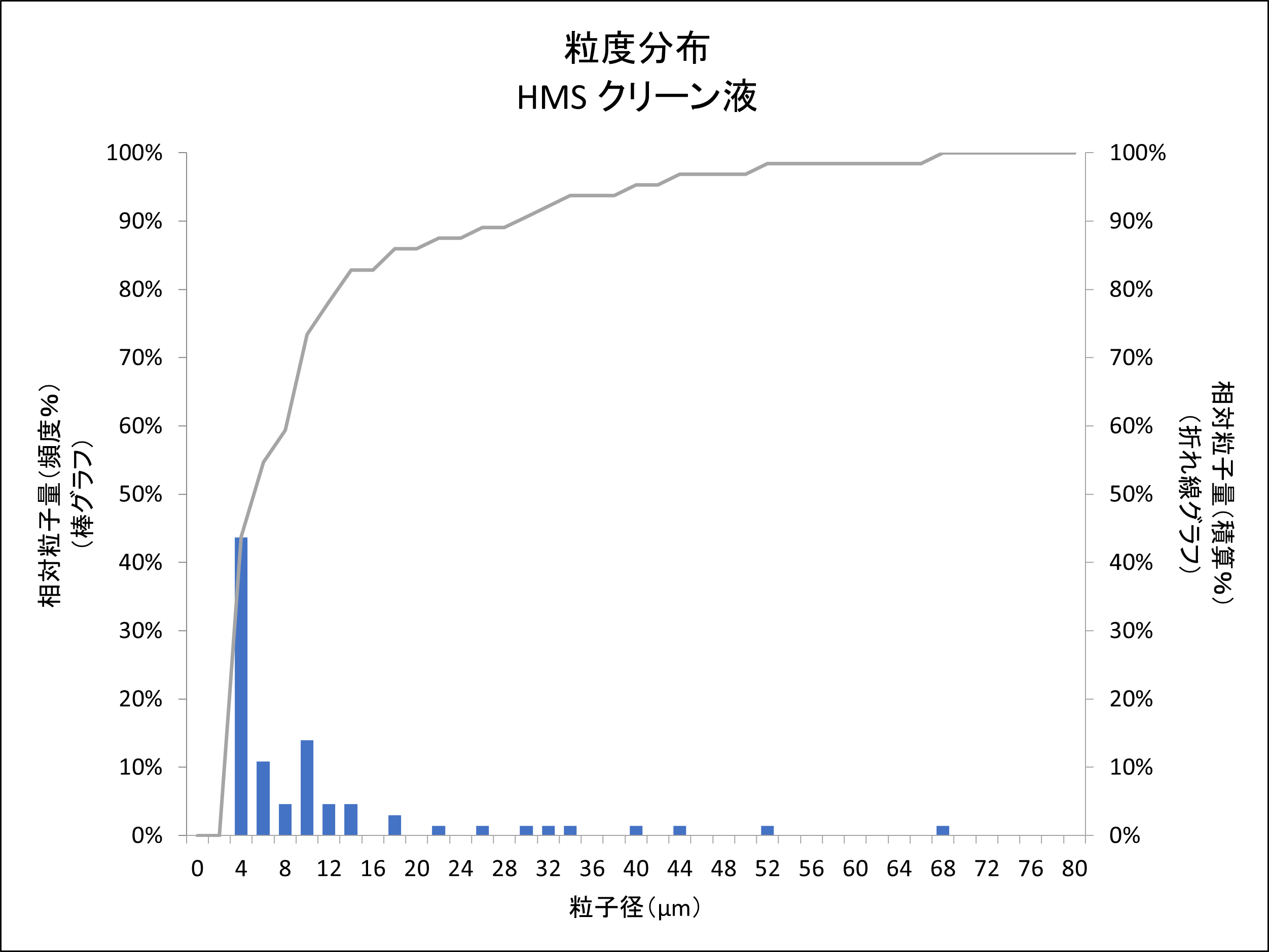

HMS

M10(#30)

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Machine tool: Inner diameter grinding machine Coolant: Water soluble Processing flow rate: 60 L/min

Chip material: Steel

Water soluble

* For details, please check the product dimensions.

* The product weight varies depending on the specifications, options, etc.

Silver gray (Munsell No. N-8.0)

*Please contact us for specific colors.

*Please contact us for details.

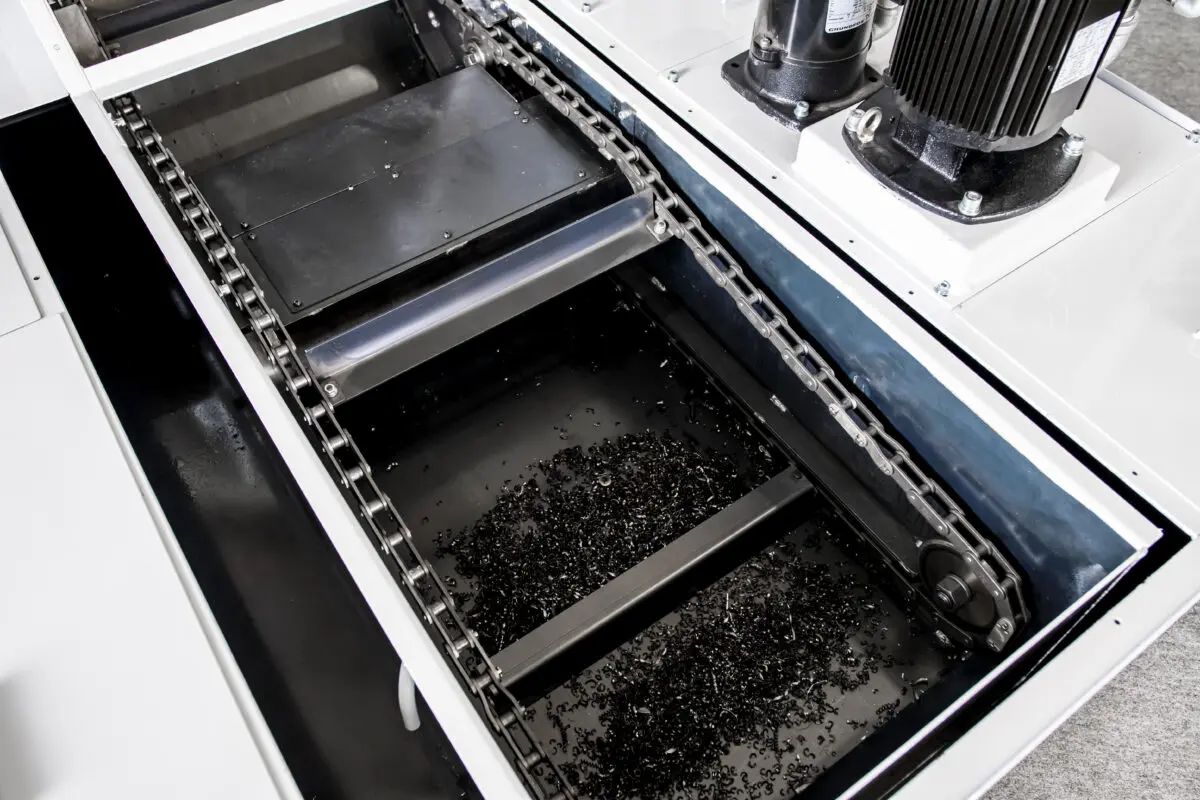

*The image is for illustrative purposes only. The specifications may differ from the actual product.

*Filtration accuracy is based on our own experiments, and we do not guarantee effectiveness.

*Specifications and dimensions are subject to change without notice.

*Please consult us if you are using oil-based products.

*Please contact us for custom-made products other than standard products.