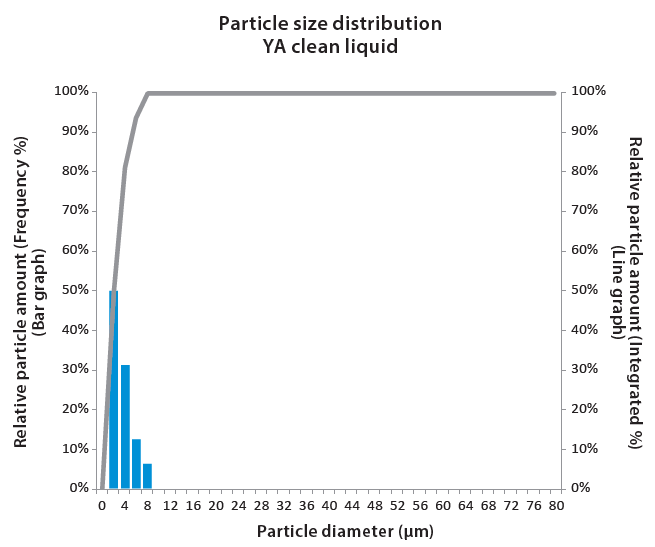

Left: Before - Dirty liquid

Right: After - Clean liquid

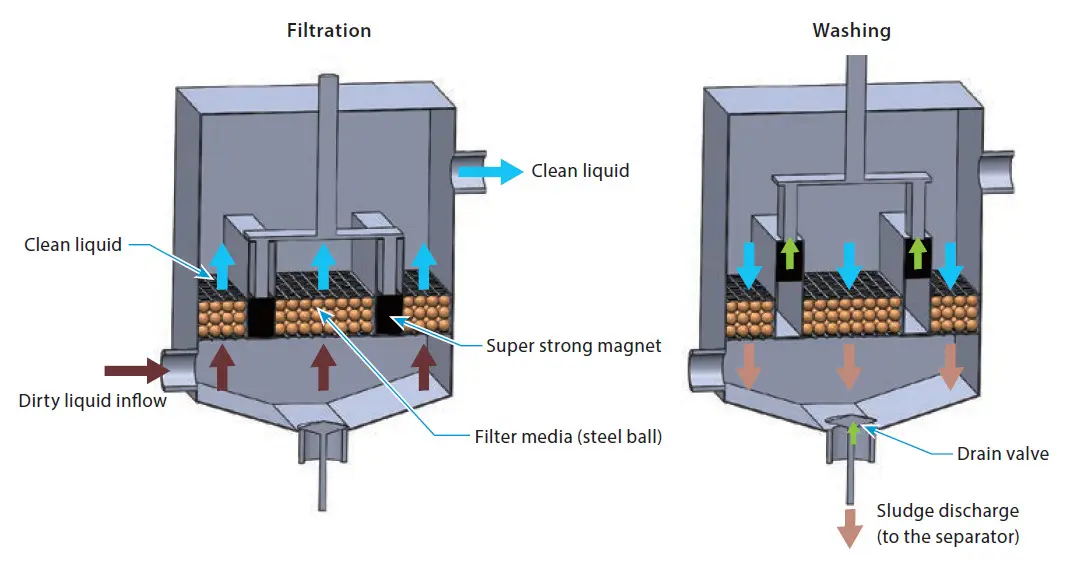

* This is the result of our experiments, and it does not imply that this level of cleaning ability has been verified.

5 μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

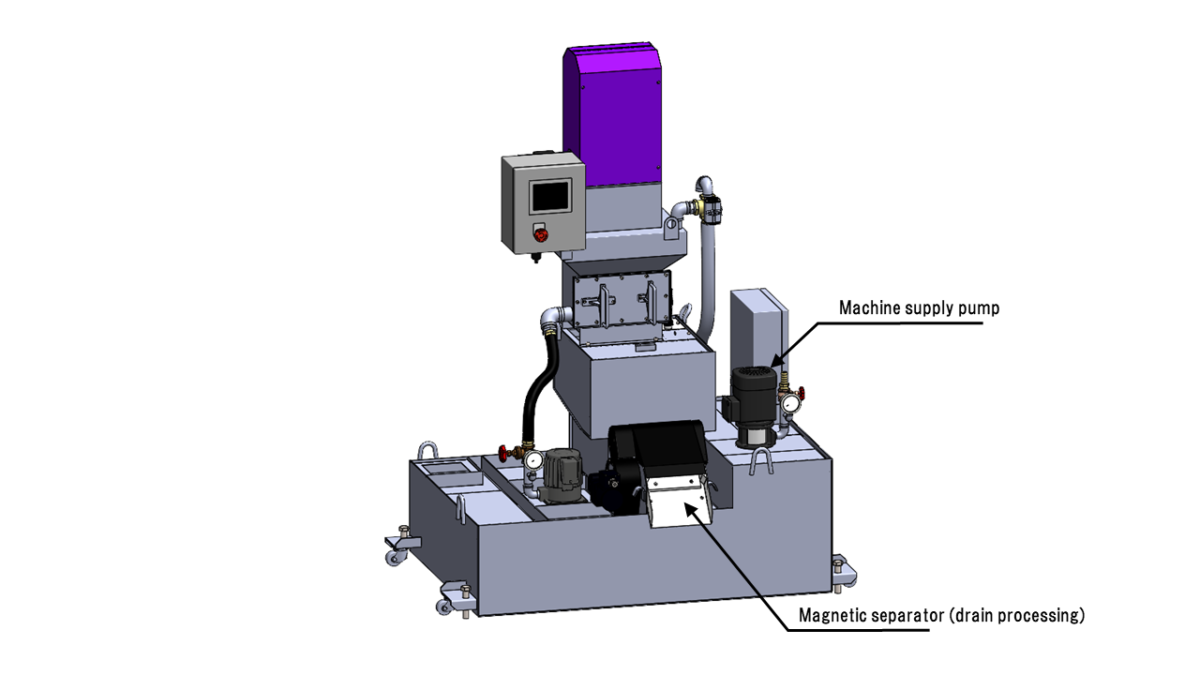

Machine tool: Grinding machine

Coolant: Water soluble

Processing flow rate: 50 L/min

Chip material: FC

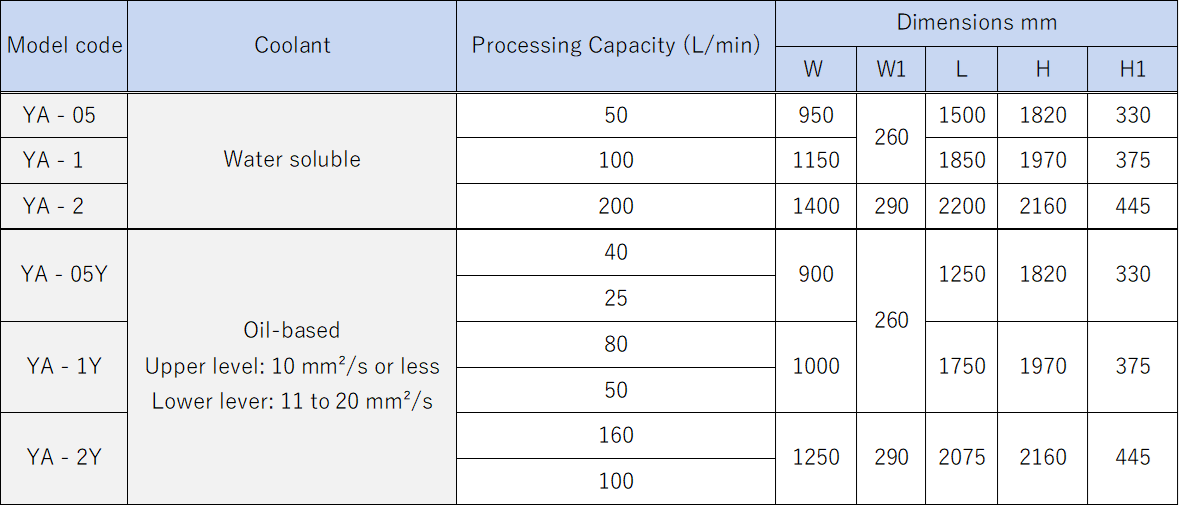

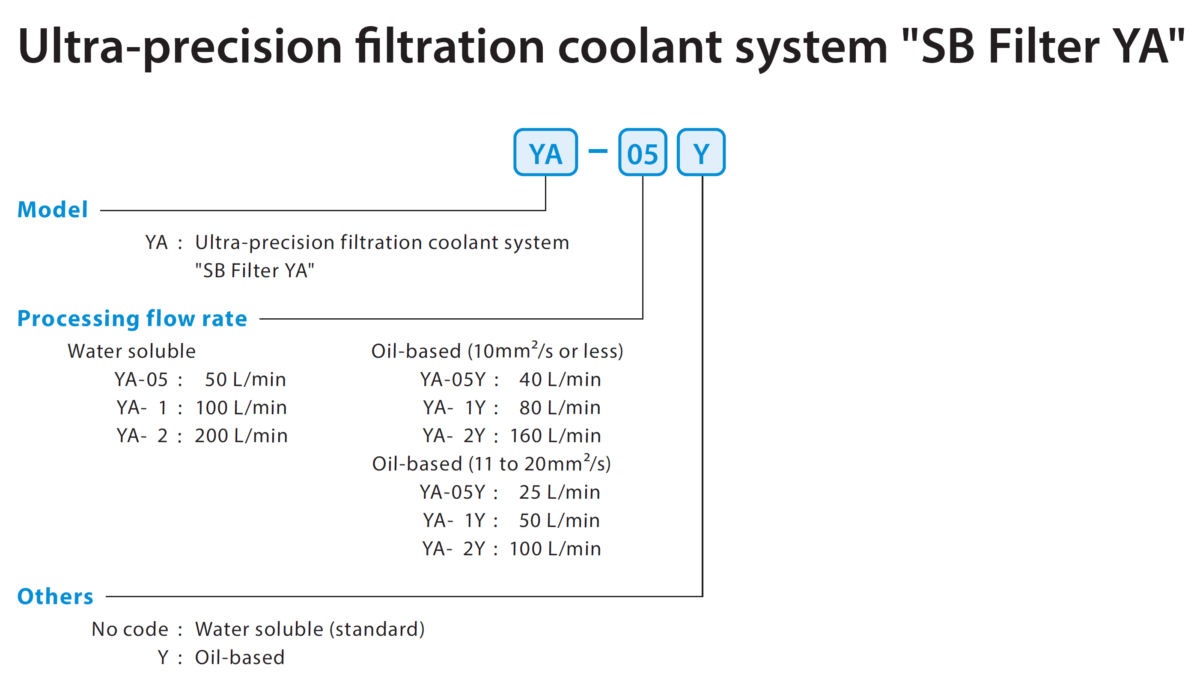

Water soluble

Oil-based (10 mm2/s or less)

Oil-based (11 to 20 mm2/s)

* When the oil viscosity exceeds 20 mm 2/s, please consult us.

* The oil viscosity is the value at 40℃.

Water soluble

Oil-based

* The product weight varies depending on the specifications, options, etc.

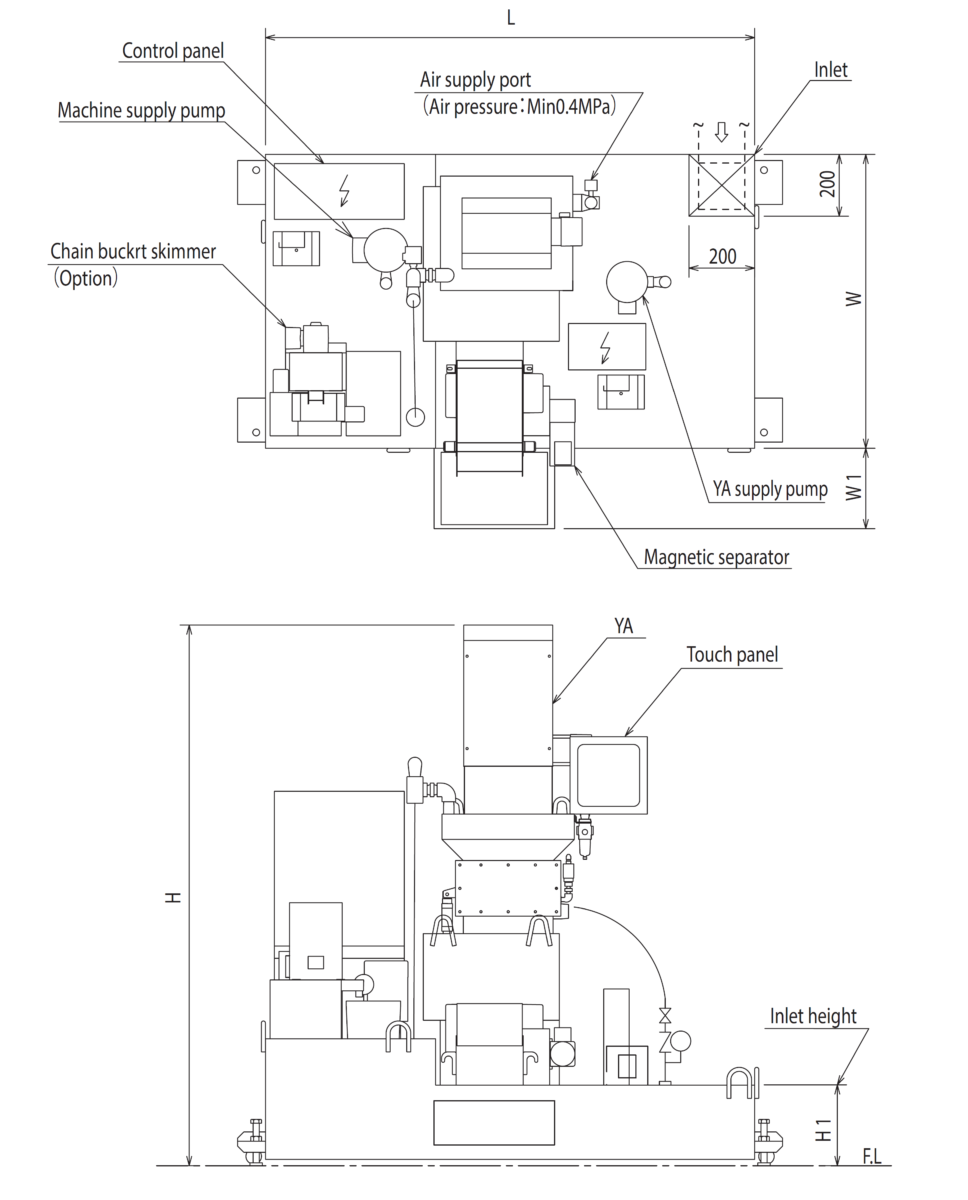

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* When the oil viscosity exceeds 20 mm 2/s, please consult us.

* The oil viscosity is the value at 40℃.

* For information about custom products other than standard products, please consult us.